How to prevent accidental breakage of connecting rod

Bolts When the connecting rod bolt breaks during operation,it will cause serious ramming accidents.It will not only cause damage to the cylinder head and cylinder liner,but also cause the connecting rod to deform and bend,and even cause major economic losses such as smashing the body and breaking the crankshaft.In order to avoid ramming accidents caused by breakage of connecting rod bolts,attention should be paid to the following points in use and maintenance:

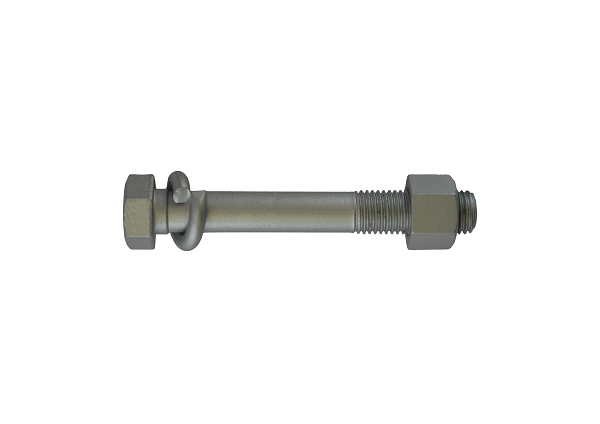

1.The connecting rod bolt is subjected to a large alternating impact load during engine operation and is an important part of the engine.It is made of high-quality alloy steel through quenched and tempered processing and precision machining.It has high strength and impact toughness and is not available.General ordinary snails or inferior parts instead.If the bolt material,heat treatment,and machining accuracy do not meet the technical requirements,the mechanical strength will not be enough and deformation and fracture will occur.

2.Check carefully before assembly.When the bolt is found to have scratches,sliding buckles,cracks,dents,necking or cracks(application of oil or magnetic inspection inspection),or bolts,nuts with loose,or bolts can not be closely matched with the bolt hole,or use Observe by contrast method,the bolt length is 2%longer than the new standard bolt length and should be replaced.